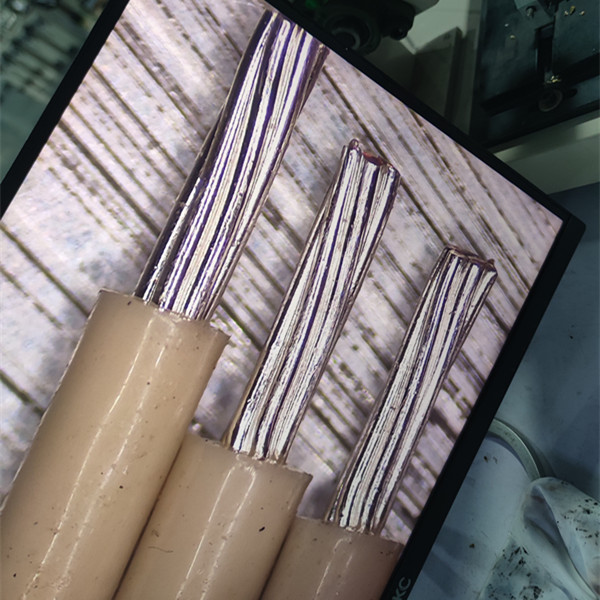

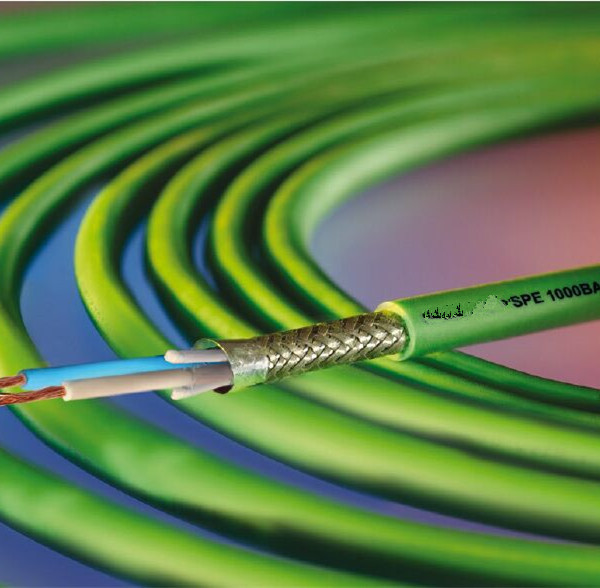

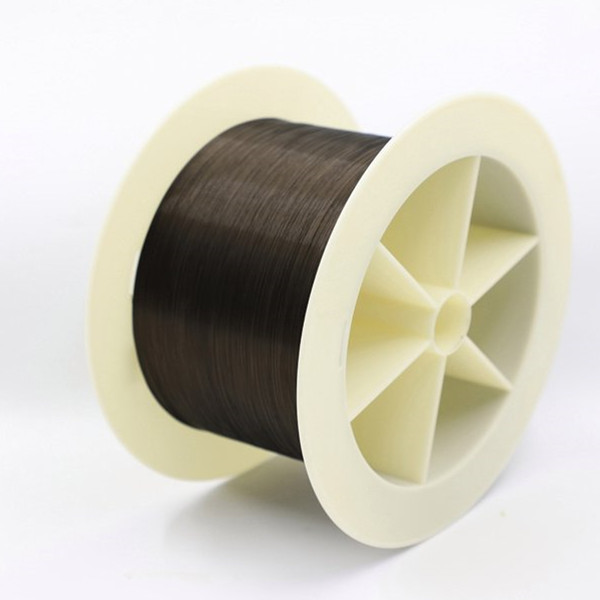

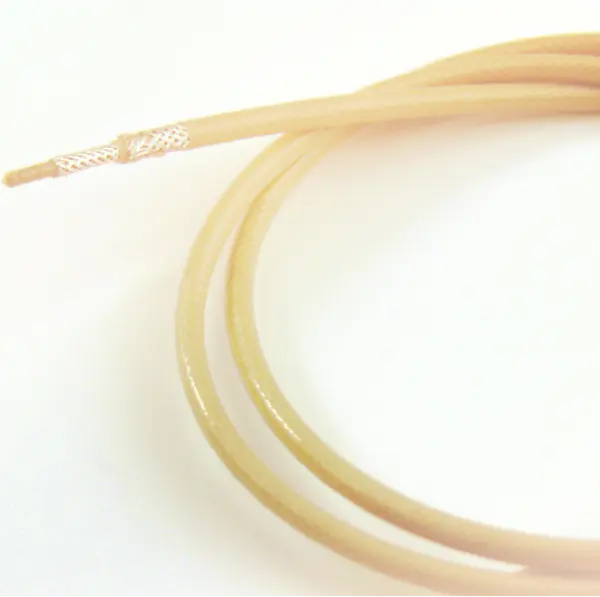

| Product Construction: | PEEK insulated wires with Silver-plated or Nickel-plated conductors |

| Conductor: | 38awg to 1/0awg |

| PEEK insulated OD: | 0.25—20.0mm |

| Environmental conditions: | a)Temperature Up to 316°C (600°F) |

| b)(Moisture 95% relative humidity Liquid Present | |

|

c) Radiation rate: Normal: up to 1 Gy/h (100 R/h) [up to 263 kGy (26 Mrads)] LOCA* up to 5 Gy/h (500 R/h) |

|

| (d) Atmosphere traces of ozone slightly Acidic | |

| Conductor Material: | All strands used in the manufacture of the conductors shall be soft annealed silver or nickel-coated copper conforming to ASTM B298 or ASTM B355. |

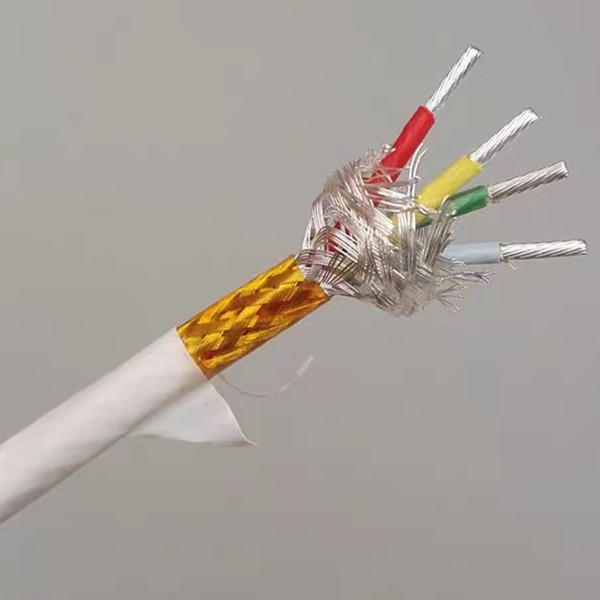

| Shield/Briad: | The shield material shall be either stainless steel, silver tin-coated or nickel-coated copper |

| Insulation Material Polyetheretherketone (PEEK) insulation material is suggested, and the primary and jacket | |

| Insulation material shall be to MIL-P-46183. |

Halogen-free PEEK cables for a safer environment In the event of a fire, using halogen-free (Low Smoke Zero Halogen) cables means there will be less smoke and no toxic fumes, offering protection for that which is most important – the safety of your rew and critical equipment.

Details

Conductor Material:All strands used in the manufacture of the conductors shall be soft annealed silver or nickel-coated copper conforming to ASTM B298 or ASTM B355.Shield/Briad:The shield material shall be either stainless steel, silver tin-coated or nickel-coated copperInsulation Material: Polyetheretherketone (PEEK) insulation material is suggested, and the primary and jacket insulation material shall be to MIL-P-46183.

Details

Peek wire cable is a high-performance cable made from polyetheretherketone, offering outstanding resistance to heat, chemicals, and wear. It is widely used in extreme industrial environments.

Details

CITCable provides custom solutions for peek wire cable tailored to meet specific industrial or technical requirements, ensuring compatibility with your needs.

Details

Peek wire cable are used in aerospace, automotive, oil and gas, and medical sectors, where durability and performance are critical under harsh conditions.

Details

CITCABLE PEEK wires Offering outstanding resistance to radiation, heat, fatigue, impact, and creep, PEEK wires are made from materials that minimize the elution of gases and metalions. PEEK wires are used in aerospace equipment, semiconductor/LCD manufacturing machine parts, medical devices, cleaning jigs, chemical equipment parts, precision machine parts, high-insulation terminals, food/beverage production equipment parts, and other products.

Details

Peek wire cable is a high-performance cable made from polyetheretherketone, offering outstanding resistance to heat, chemicals, and wear. It is widely used in extreme industrial environments.

Details

A semi-crystalline thermoplastic, PEEK, TPI, POLYIMIDE, ETFE offers excellent mechanical properties and chemical resistance coupled with outstanding thermal and combustion characteristics.PEEK, TPI, POLYIMIDE, ETFE cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion.

Details

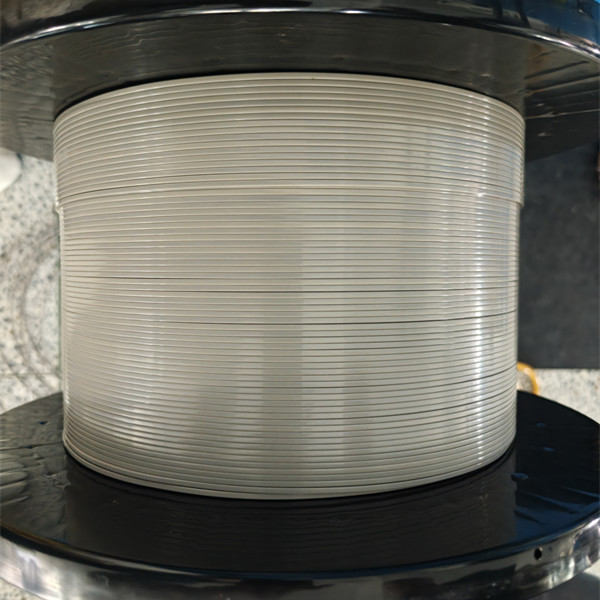

CITCABLE can make a crystalline, A semi-crystalline, non-crystalline peek wire cables, PEEK offers excellent mechanical properties and chemical resistance coupled with outstanding thermal and combustion characteristics. Typical applications include nuclear power wiring, chemical processing, and ultrahigh vacuum (UHV) environments,PEEK insulated wire is available by custom order and in crystalline and amorphous; we can extrude this material in round, square. We can also provide PEEK insulated wire in stranded and other wire.

Details

The peek wire cable operates effectively in a wide temperature range, typically up to 260°C, making it suitable for high-temperature applications.

Details

Peek wire cable offers excellent chemical resistance, making it ideal for industries requiring exposure to harsh solvents, fuels, or corrosive materials.

Details

260°C PEEK Enamelled Wire, solid copper with peek insulation for Motor The Ideal solution for Coil Winding and Magnet wire

Details

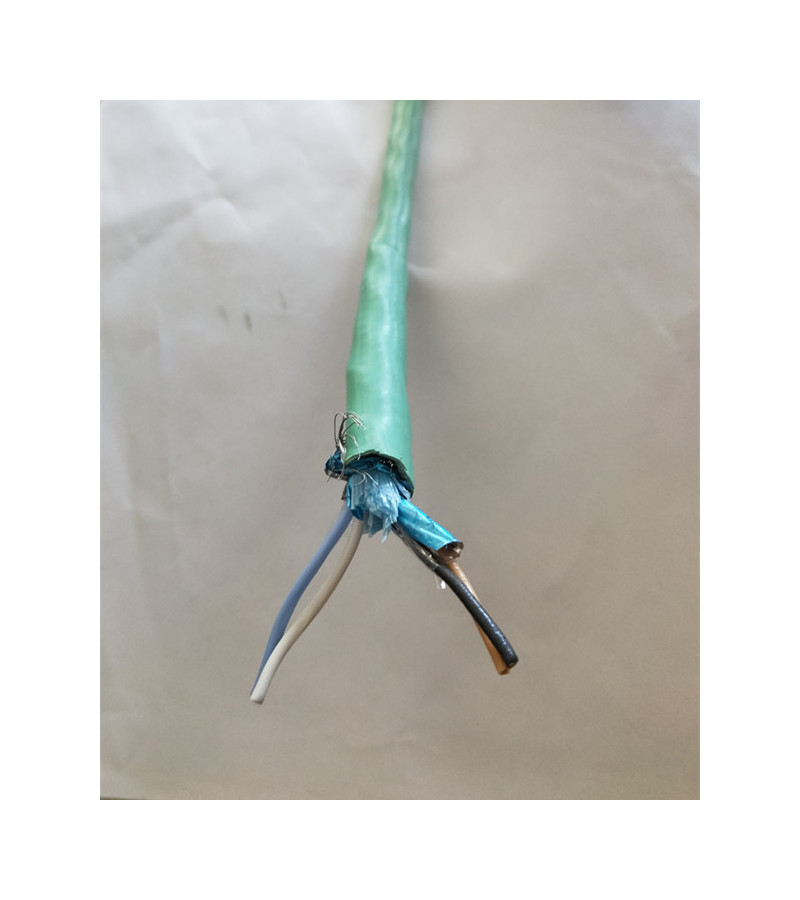

Nuclear Industry Cables CITCable manufactures custom cable for the nuclear industry. Our nuclear cable is designed to withstand the harsh environments encountered in nuclear power plants. We engineer cables using only premium radiation resistant insulation and jacketing materials.Our nuclear cables are used as probe cables, sensor cables, composite instrument and power cables, and in numerous other configurations and applications. CITCable can help you engineer a custom cable solution for your particular nuclear industry application

Details

Peek wire cable are used in aerospace, automotive, oil and gas, and medical sectors, where durability and performance are critical under harsh conditions.

Details

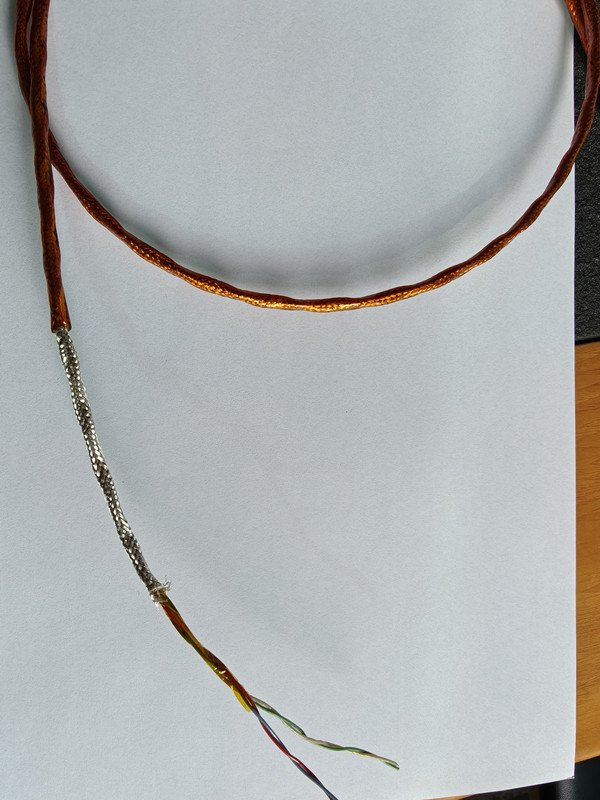

High Temperature Robotics Cable High Temperature manufactures specialty robotics cable that combines high flex life with rugged construction. Using special high-flex conductors and durable jacketing materials, our robotics cable is designed to withstand all kinds of continuous flexing applications.CITCable design our robotics cable with your application in mind to deliver the performance and extra long working life needed for industrial robotics and other automated machinery applications. CITCable can help you engineer a custom cable solution for your particular robotics cable

Details

CITCABLE PEEK wires Offering outstanding resistance to radiation, heat, fatigue, impact, and creep, PEEK wires are made from materials that minimize the elution of gases and metalions.

Details

PEEK Insulated Wire is designed specifically for use in challenging environments within the oil and gas, automotive, aerospace and electrical industries. With dielectric strength of over 6,0000 v/ mil and a continuous service temperature of 260°C (500°F).

Details

CITCABLE: PEEK WIRE HANRESS High Temperature Sensor Cable is suitable for both indoor and outdoor applications. Its robust construction and resistance to extreme temperatures, UV exposure, and environmental elements make it ideal for use in outdoor installations. Whether it's used in remote monitoring systems, outdoor machinery, or temperature sensing for weather-sensitive operations, this cable ensures durability and reliability, even when exposed to the elements.

Details

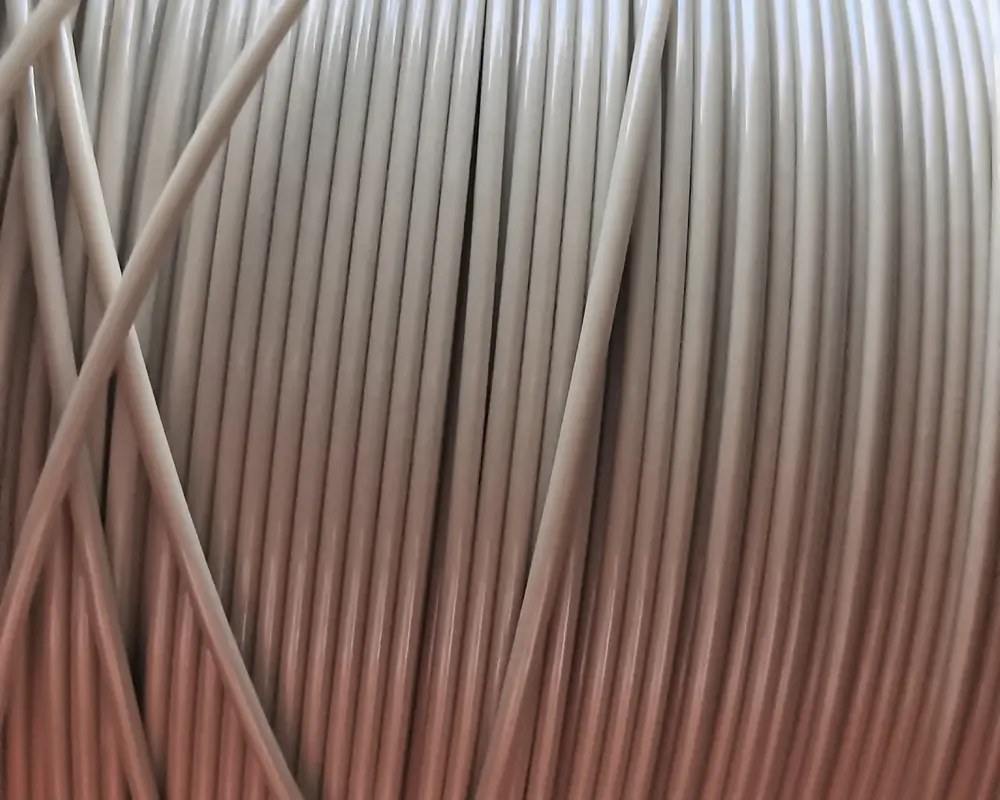

PEEK insulated wires with Silver-plated or Nickel-plated conductorsConductor: 38awg to 1/0awg,PEEK insulated OD: 0.20—30.0mm

Details

CITCABLE: High Temperature PEEK RTD Cable CITCable extrudes all types of PEEK,PEI,TPI,PI,FEP,PFA,PTFE,ETFE,PVDF,Viton/FKM/FPM, SILICONE and Wrap PI,PTFE,others, CITCABLE can accommodate large power cables as well as miniature control cables.

Details

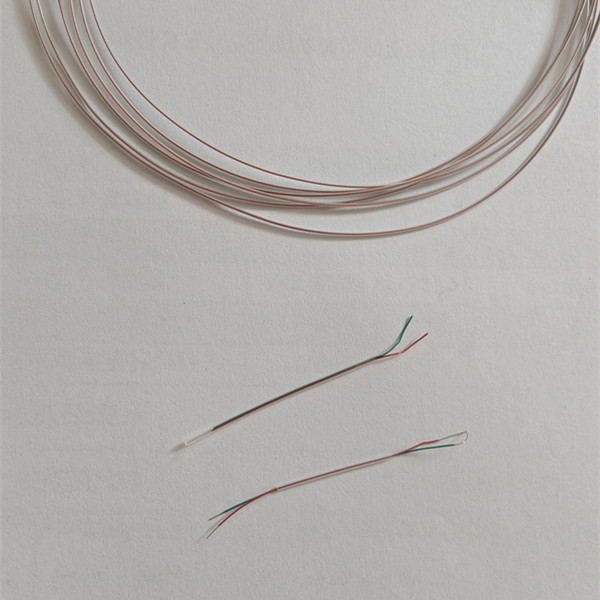

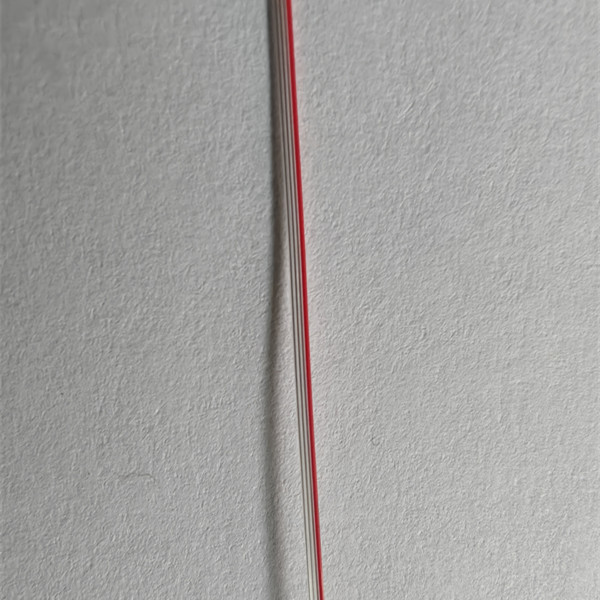

CITCABLE: 260°C Ultra thin PEEK Wire cable and TPI Coated/TEFLON Coated/OTHERS Coateds K TYPE THERMOCOUPLE 36AWG 0.127 PEEK OD:0.20MM TYPE KN ,GREEN K TYPE THERMOCOUPLE 36AWG 0.127 PEEK OD:0.20MM TYPE KP ,RED K TYPE THERMOCOUPLE 30AWG 0.25 OD:0.30MM TYPE KN ,GREENK TYPE THERMOCOUPLE 30AWG 0.25 OD:0.30MM TYPE KP ,REDK TYPE THERMOCOUPLE 30AWG 0.25 OD:0.41MM TYPE KN ,GREENK TYPE THERMOCOUPLE 30AWG 0.25 OD:0.41MM TYPE KP ,REDJ TYPE THERMOCOUPLE 30AWG 0.26 ,0.41MM TYPE JN GREENJ TYPE THERMOCOUPLE 30AWG 0.26 ,0.41MM TYPE JP RED,GARY,BLUE,WHITEK ,J,T, TYPE THERMOCOUPLE conductors 0.32MM, OD:0.55MM , flat duplex insulated or a pair individually PEEKK ,J,T, TYPE THERMOCOUPLE conductors 0.65MM, OD:0.90MM , flat duplex insulated or a pair individually PEEK High Temperature Sensor Cable is primarily used in applications where accurate temperature measurement is crucial, such as in aerospace, automotive, industrial automation, and power generation. It is designed to withstand extreme heat while providing reliable data for temperature-sensitive equipment. Whether used for engine sensors, temperature probes, or industrial controllers, this cable ensures optimal performance in high-temperature environments, offering stability and precision even in the harshest conditions. 1/0AWG to #40 AWG sizes (OD:0.12--20.0mm) • Wall thickness ranging from (0.03 mm - 2.81 mm)• 100% spark tested during extrusion• Amorphous or crystalline PEEK Insulated Wire available• Round, stranded, square and rectangular profiles available• Various types of wire available, including silver and nickel-plated wire as well as custom wire types Looking for a halogen-free, flame-retardant material with unbeatable radiation resistance and safe to operate up to 260°C,Look no further than PEEK. A core insulating material in many of our cables, PEEK is ideal for demanding environments like nuclear power reactors or vehicle exhaust sensors.

Details

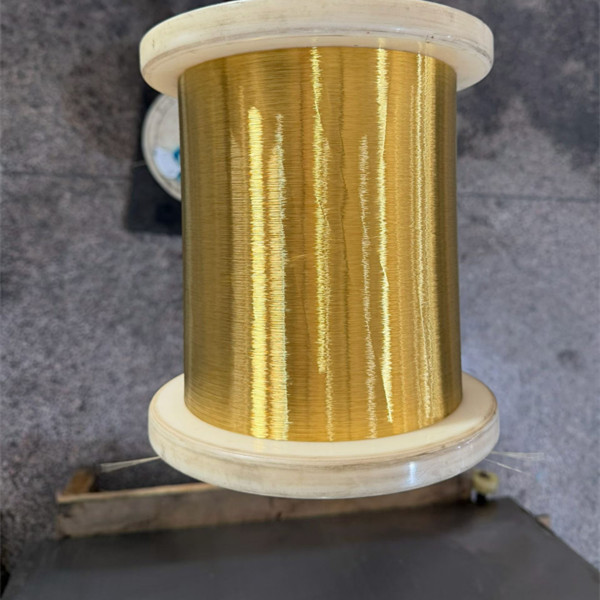

CITCABLE:PEEK flat wire for hairpin stator ITCABLE PEEK wire cable offerings are ideally suited for electric motors, generators, transformers, solenoids,Wire and Cable – When high performance is needed in wire and cable Applications. PEEK wire is available with insulation thickness ranging from 0.025 mm to0.381 mm and Wire Gauge (AWG) sizes #3/0 to #40.Both PEEK insulated wire and PEEK wire HB are 100% AC spark tested during extrusion. Both PEEK insulated wire and PEEK wire HB are available by custom order. PEEK wire HB utilizing bare annealed solid round copper wire meets ASTM B-3 standards.We can coat both wires in round, square, and rectangular profiles. We can also provide PEEK insulated wire over stranded, plated, and other wire forms. Splicing can be accomplished using.

Details

CITCABLE: PEEK high temp cable CITCABLE PEEK wire cable offerings are ideally suited for electric motors, generators, transformers, solenoids,Wire and Cable – When high performance is needed in wire and cable applications. PEEK wire is available with insulation thickness ranging from 0.025 mm to0.381 mm and Wire Gauge (AWG) sizes #3/0 to #40.Both PEEK insulated wire and PEEK wire HB are 100% AC spark tested during extrusion. Both PEEK insulated wire and PEEK wire HB are available by custom order. PEEK wire HB utilizing bare annealed solid round copper wire meets ASTM B-3 standards.We can coat both wires in round, square, and rectangular profiles. We can also provide PEEK insulated wire over stranded, plated, and other wire forms. Splicing can be accomplished using.

Details

CITCABLE: Aluminum Alloy PEEK wire CITCABLE PEEK wire cable offerings are ideally suited for electric motors, generators, transformers, solenoids,Wire and Cable – When high performance is needed in wire and cable PEEK wire is available with insulation thickness ranging from 0.025 mm to0.381 mm and Wire Gauge (AWG) sizes #3/0 to #40.Both PEEK insulated wire and PEEK wire HB are 100% AC spark tested during extrusion. Both PEEK insulated wire and PEEK wire HB are available by custom order. PEEK wire HB utilizing bare annealed solid round copper wire meets ASTM B-3 standards.We can coat both wires in round, square, and rectangular profiles. We can also provide PEEK insulated wire over stranded, plated, and other wire forms. Splicing can be accomplished using.

Details

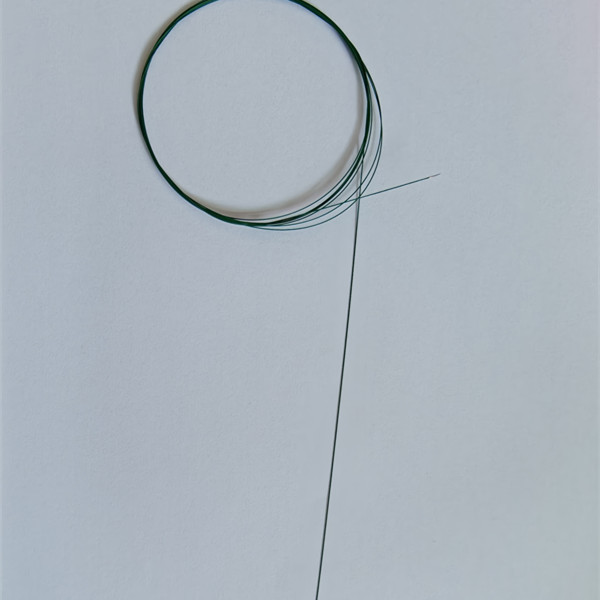

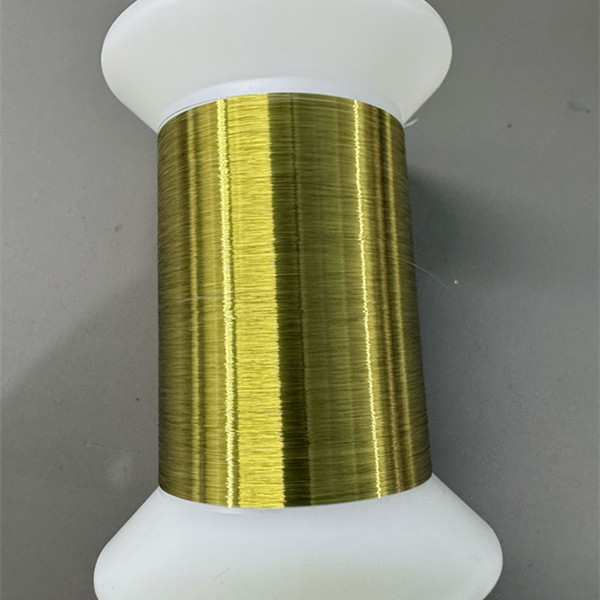

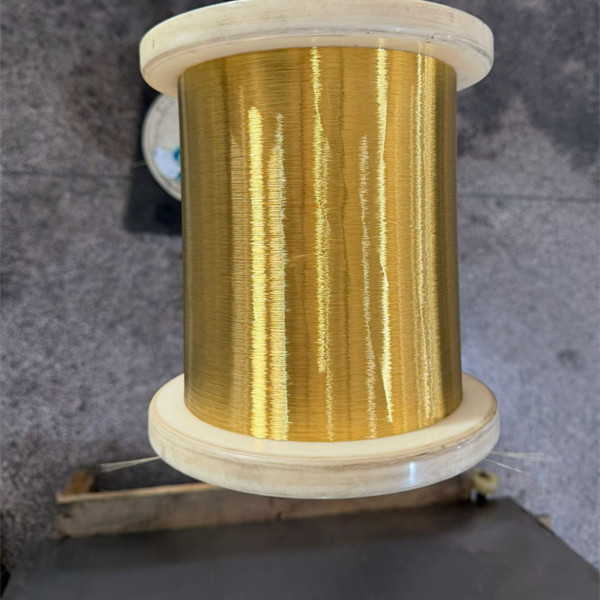

Tungsten Wire With Polyimide / Kapton Coating CITCABLE: Thin-Wall Polyimide Coating wire We provideThin-Wall Polyimide Coating wire sensor cable products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: Pure Silver, Nickel or Silver, Nickel plated copper with a purity of ≥ 99.99% · Tungsten Diameter: 0.08 mm ± 0.005 mm · Polyimide / Kapton Diameter: 0.20 mm ± 0.01 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production

Details

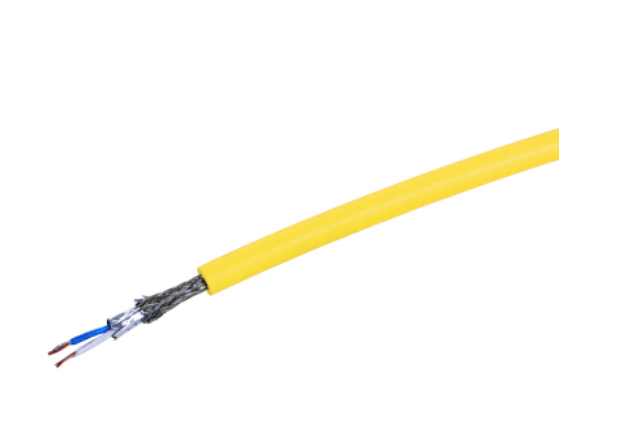

CITCABLE: Foam FEP Plenum Rated Cable Foam FEP cables For Plenum Rated Flexible Fluorpolymer Plenum (cat5,RG, Canbus,SPE and so on ) 100ohm, 120ohm Foam FEP twisted par data cables with heat resistant up to 250° We can meet your industry specific requirements promptly as we are equipped with advanced in-house wire and cable manufacturing equipment.We assure on time product delivery, whilst meeting all product quality expectations.

Details

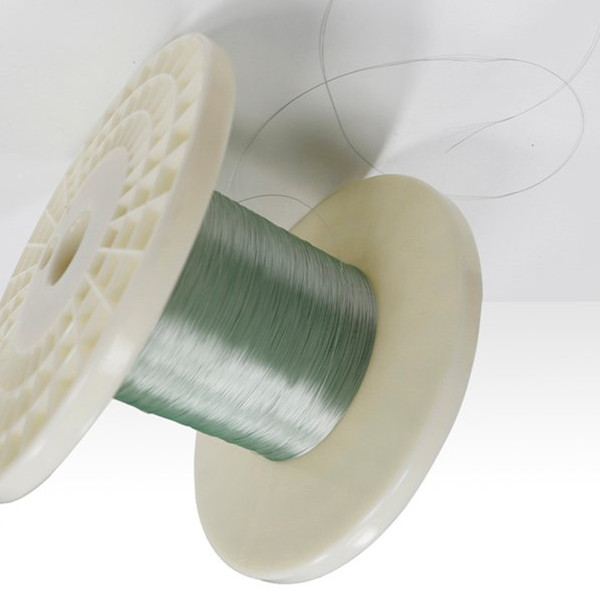

CITCABLE:Super fine Polyimide / Kapton Coating Wire Cable We provideSuper fine Polyimide / Kapton Coating Wire Cable for sensor products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: Pure Silver, Nickel or Silver, Nickel plated copper with a purity of ≥ 99.99% · Tungsten Diameter: 0.05 mm ± 0.005 mm · Polyimide / Kapton Diameter: 0.10 mm ± 0.01 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production

Details

CITCABLE :high temperature Canbus Cat SPE Foam Fep Cables Foam FEP cables For Canbus, Cat ,SPE Flexible Fluorpolymer Plenum (cat5,RG, Canbus,SPE and so on ) 100ohm, 120ohm Foam FEP twisted par data cables with heat resistant up to 250° We can meet your industry specific requirements promptly as we are equipped with advanced in-house wire and cable manufacturing equipment.We assure on time product delivery, whilst meeting all product quality expectations.

Details

CITCABLE:Flat Kapton Wire We provideThin-Wall Polyimide Coating wire sensor cable products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: Pure Silver, Nickel or Silver, Nickel plated copper with a purity of ≥ 99.99% · Tungsten Diameter: 0.08 mm ± 0.005 mm · Polyimide / Kapton Diameter: 0.20 mm ± 0.01 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production

Details

CITCABLE:180mmsq PEEK Cable CITCable manufactures custom cable for the nuclear industry. Our nuclear cable is designed to withstand the harsh environments encountered in nuclear power plants. We engineer cables using only premium radiation resistant insulation and jacketing materials.Our nuclear cables are used as probe cables, sensor cables, composite instrument and power cables, and in numerous other configurations and applications. CITCable can help you engineer a custom cable solution for your particular nuclear industry application

Details

CITCABLE:TPI Coating Cable CIT cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion. Polyimide (PI) is a group of high performing polymers known for their exceptional chemical, thermal, and mechanical performance properties. These materials demonstrate exceptional thermal stability in high and low temperatures and are extremely flame resistant. PI , CITCABLE PI / TEFLON composite, is a high lubricity polyimide blend for applications that require lower surface friction yet do not require the performance of pure TEFLON. Polyimide maintains broad chemical resistance and good dielectric properties in addition to its reduced coefficient of friction

Details

CITCABLE: High Temperature Foam FEP Cable Foam FEP cables For Canbus, Cat ,SPE Flexible Fluorpolymer Plenum (cat5,RG, Canbus,SPE and so on ) 100ohm, 120ohm Foam FEP twisted par data cables with heat resistant up to 250° We can meet your industry specific requirements promptly as we are equipped with advanced in-house wire and cable manufacturing equipment.We assure on time product delivery, whilst meeting all product quality expectations.

Details

CITCABLE radiation resistant sigle-mode fibres are developed by adjusting the composition of optical fibre and improving the process technology to meet the special application requirements of the fibre in the radiation environment. The optical properties are optimized at 1310nm and 1550nm oprerating wavelenghth. Low attenuation and low dispersion can be achieved.

Details

CITCABLE: Thin-Wall Polyimide medical Wire We provideThin-Wall Polyimide/PI MEDICAL wire sensor cable products. If you are interested in high temperature MEDICAL sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: Pure Silver, Nickel or Silver, Nickel plated copper with a purity of ≥ 99.99% · Diameter: 0.12mm ± 0.005 mm · Polyimide / Kapton Diameter: 0.142 mm ± 0.005 mm Coating Requirements: · Type: Polyimide / Kapton/PI · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production

Details

CITCABLE: TPX insulator Wire Cable CITCABLE can custom manufacture No PFAS Alternatives Flexible Cable and wire with a vast range of conductors and thermoplastic insulation to meet our customers’ specifications. We manufacture Flexible Cable and Flexible Wire in custom sizes as small as AWG 40--AWG1/0 In addition, CITCABLE has the expertise and experience in employing the kinds of thin-wall cable jacketing and insulation that many applications require. PFASs stand for per- and polyfluoroalkyl substances and are defined as fluorinated substances that contain at least one fully fluorinated methyl or methylene carbon atom except any H, Cl, Br and I atom connected. It includes almost every organo-fluorine compound in the world. Because of their excellent properties, including heat resistance, chemical resistance, flame resistance, and oil resistance, organo-fluorine compounds are used in a wide range of products that are indispensable to our daily lives. On the other hand, their outstanding durability makes them difficult to decompose in the natural world, raising concerns about their impact on the environment and human health. US EPA is mandating PFAS reporting rules and several US states have enacted state bans on PFAS in personal care and food packaging products

Details

TPX Insulator Wire Cable CITCABLE: FREE PFAS Wire Cable CITCABLE can custom manufacture No PFAS Alternatives Flexible Cable and wire with a vast range of conductors and thermoplastic insulation to meet our customers’ specifications. We manufacture Flexible Cable and Flexible Wire in custom sizes as small as AWG 40--AWG1/0 In addition, CITCABLE has the expertise and experience in employing the kinds of thin-wall cable jacketing and insulation that many applications require.

Details

CITCABLE: TPX insulator Wire Cable CITCABLE can custom manufacture No PFAS Alternatives Flexible Cable and wire with a vast range of conductors and thermoplastic insulation to meet our customers’ specifications. We manufacture Flexible Cable and Flexible Wire in custom sizes as small as AWG 40--AWG1/0 In addition, CITCABLE has the expertise and experience in employing the kinds of thin-wall cable jacketing and insulation that many applications require. PFASs stand for per- and polyfluoroalkyl substances and are defined as fluorinated substances that contain at least one fully fluorinated methyl or methylene carbon atom except any H, Cl, Br and I atom connected. It includes almost every organo-fluorine compound in the world. Because of their excellent properties, including heat resistance, chemical resistance, flame resistance, and oil resistance, organo-fluorine compounds are used in a wide range of products that are indispensable to our daily lives. On the other hand, their outstanding durability makes them difficult to decompose in the natural world, raising concerns about their impact on the environment and human health.

Details

CITCABLE ;NO PFASs WIRE CABLE TPX,TPI,PAI,PEEK ,PEI CABLES CITCABLE can custom manufacture No PFAS Alternatives Flexible Cable and wire with a vast range of conductors and thermoplastic insulation to meet our customers’ specifications. We manufacture Flexible Cable and Flexible Wire in custom sizes as small as AWG 40--AWG1/0 In addition, CITCABLE has the expertise and experience in employing the kinds of thin-wall cable jacketing and insulation that many applications require. Heat resistance: FREE PFAS , TPX, PEEK, TPI ,PEI wire cable Can be used under higher temperatures compared to other polyolefins because of high melting point Electric properties: FREE PFAS TPX, PEEK, TPI ,PEI wire cable exhibits low dielectric properties across a broad frequency range Moldability: FREE PFAS TPX, PEEK, TPI ,PEIwire cable Can be molded at lower temperatures than fluoropolymers

Details

CITCABLE:Thin-Wall Polyimide S316L medical Wire We provideTungsten wire with Polyimide / Kapton/PEEK/PI/ETFE/PTFE/TPX Coating sensor cable products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: White Tungsten with a purity of ≥ 99.95% · Tungsten/S316L/S304 Diameter: 0.08 mm ± 0.001 mm · Polyimide / Kapton Diameter: 0.12 mm ± 0.01 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK/PI/ETFE/PTFE/TPX · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production · Handling: Components must not be touched with latex glove

Details

CITCABLE:Super Fine PI Coating S304 Wire We provideSuper fine Polyimide / Kapton/PI Coating Wire Cable for sensor products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: Pure Silver, Nickel or Silver, Nickel plated copper with a purity of ≥ 99.99% · Tungsten Diameter: 0.03mm ± 0.003 mm · Polyimide / Kapton/PI Diameter: 0.05 mm ± 0.01 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK/PI/PEI/PTFE/ETFE/TPX · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production

Details

CITCABLE: FLAT Ribbon Telon CABLE from 10awg to 42awg TEFLON offers outstanding resistance to chemicals, oils and lubricants, retains it’s flexibility at low temperatures and has good weatherability. CITCables are a specialist Cable manufacturer who can produce a broad range of custom designed High Temperature Sensor Wires & Cables for use in the most challenging and extreme environments. We produce a core range of sensor wires & cable that are all designed and manufactured in our own factory. We can also build a bespoke solution if you require something very specific. Key Characteristics Available with Nickel ,Silver-Plated or Tin-Plated Conductor Superior dielectrical properties Nonflammable Applications 1. Military Communications Systems2. Aerospace and Aircraft Wiring3. OEM Appliance Wiring4. Electronics Wiring5. Medical Wiring

Details

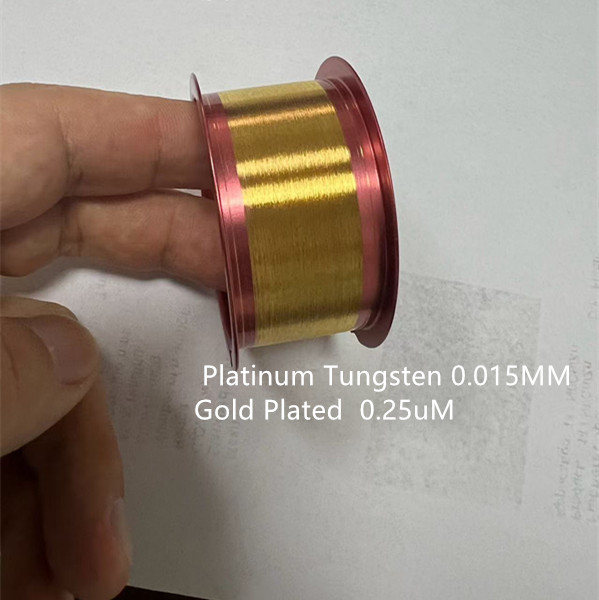

CITCABLE: Platinum Tungsten Polyimide coating for medical Wire Platinum Tungsten (Pt/W) 、 Platinum Iridium (Pt/Ir) 、 Platinum Nickel (Pt/Ni) We provideTungsten wire with Polyimide / Kapton/PEEK/PI/ETFE/PTFE/TPX Coating sensor cable products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: White Tungsten with a purity of ≥ 99.95% · Tungsten/S316L/S304 Diameter: 0.03 mm ± 0.001 mm · Polyimide / Kapton Diameter: 0.035 mm ± 0.001 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK/PI/ETFE/PTFE/TPX · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production · Handling: Components must not be touched with latex glove

Details

CITCABLE: Platinum Tungsten Polyimide coating for medical Wire Platinum Tungsten (Pt/W) 、 Platinum Iridium (Pt/Ir) 、 Platinum Nickel (Pt/Ni) We provideTungsten wire with Polyimide / Kapton/PEEK/PI/ETFE/PTFE/TPX Coating sensor cable products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: White Tungsten with a purity of ≥ 99.95% · Tungsten/S316L/S304 Diameter: 0.03 mm ± 0.001 mm · Polyimide / Kapton Diameter: 0.035 mm ± 0.001 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK/PI/ETFE/PTFE/TPX · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production · Handling: Components must not be touched with latex glove

Details

CITCABLE: Platinum Tungsten Polyimide coating for medical Wire Platinum Tungsten (Pt/W) 、 Platinum Iridium (Pt/Ir) 、 Platinum Nickel (Pt/Ni) We provideTungsten wire with Polyimide / Kapton/PEEK/PI/ETFE/PTFE/TPX Coating sensor cable products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: White Tungsten with a purity of ≥ 99.95% · Tungsten/S316L/S304 Diameter: 0.03 mm ± 0.001 mm · Polyimide / Kapton Diameter: 0.035 mm ± 0.001 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK/PI/ETFE/PTFE/TPX · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production · Handling: Components must not be touched with latex glove

Details

CITCABLE: Aluminum Alloy 1350 PEEK WIRES CITCable manufactures custom cable for the nuclear industry. Our nuclear cable is designed to withstand the harsh environments encountered in nuclear power plants. We engineer cables using only premium radiation resistant insulation and jacketing materials.Our nuclear cables are used as probe cables, sensor cables, composite instrument and power cables, and in numerous other configurations and applications. CITCable can help you engineer a custom cable solution for your particular nuclear industry application

Details

CITCABLE PEEK wire cable offerings are ideally suited for electric motors, generators, transformers, solenoids,Wire and Cable – When high performance is needed in wire and cable applications.

Details

CITCABLE: 260°C Ultra thin PEEK Wire cable and TPI Coated/TEFLON Coated/OTHERS Coateds K TYPE THERMOCOUPLE 36AWG 0.127 PEEK OD:0.20MM TYPE KN ,GREEN K TYPE THERMOCOUPLE 36AWG 0.127 PEEK OD:0.20MM TYPE KP ,RED K TYPE THERMOCOUPLE 30AWG 0.25 OD:0.30MM TYPE KN ,GREENK TYPE THERMOCOUPLE 30AWG 0.25 OD:0.30MM TYPE KP ,REDK TYPE THERMOCOUPLE 30AWG 0.25 OD:0.41MM TYPE KN ,GREENK TYPE THERMOCOUPLE 30AWG 0.25 OD:0.41MM TYPE KP ,REDJ TYPE THERMOCOUPLE 30AWG 0.26 ,0.41MM TYPE JN GREENJ TYPE THERMOCOUPLE 30AWG 0.26 ,0.41MM TYPE JP RED,GARY,BLUE,WHITEK ,J,T, TYPE THERMOCOUPLE conductors 0.32MM, OD:0.55MM , flat duplex insulated or a pair individually PEEKK ,J,T, TYPE THERMOCOUPLE conductors 0.65MM, OD:0.90MM , flat duplex insulated or a pair individually PEEK High Temperature Sensor Cable is primarily used in applications where accurate temperature measurement is crucial, such as in aerospace, automotive, industrial automation, and power generation. It is designed to withstand extreme heat while providing reliable data for temperature-sensitive equipment. Whether used for engine sensors, temperature probes, or industrial controllers, this cable ensures optimal performance in high-temperature environments, offering stability and precision even in the harshest conditions. 1/0AWG to #46 AWG sizes (OD:0.10--20.0mm) • Wall thickness ranging from (0.03 mm - 2.81 mm)• 100% spark tested during extrusion• Amorphous or crystalline PEEK Insulated Wire available• Round, stranded, square and rectangular profiles available• Various types of wire available, including silver and nickel-plated wire as well as custom wire types Looking for a halogen-free, flame-retardant material with unbeatable radiation resistance and safe to operate up to 260°C,Look no further than PEEK. A core insulating material in many of our cables, PEEK is ideal for demanding environments like nuclear power reactors or vehicle exhaust sensors.

Details

PEEK cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion.

Details

CITCABLE: Kapton Cable CIT cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion. Polyimide (PI) is a group of high performing polymers known for their exceptional chemical, thermal, and mechanical performance properties. These materials demonstrate exceptional thermal stability in high and low temperatures and are extremely flame resistant. PI , CITCABLE PI / TEFLON composite, is a high lubricity polyimide blend for applications that require lower surface friction yet do not require the performance of pure TEFLON. Polyimide maintains broad chemical resistance and good dielectric properties in addition to its reduced coefficient of friction

Details

CITCABLE: CMP Foam FEP Cable Foam FEP cables For Canbus, Cat ,SPE Flexible Fluorpolymer Plenum (cat5,RG, Canbus,SPE and so on ) 100ohm, 120ohm Foam FEP twisted par data cables with heat resistant up to 250° We can meet your industry specific requirements promptly as we are equipped with advanced in-house wire and cable manufacturing equipment.We assure on time product delivery, whilst meeting all product quality expectations.

Details

CITCABLE: Kapton Wire We provideThin-Wall Polyimide Coating wire sensor cable products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: Pure Silver, Nickel or Silver, Nickel plated copper with a purity of ≥ 99.99% · Tungsten Diameter: 0.08 mm ± 0.005 mm · Polyimide / Kapton Diameter: 0.20 mm ± 0.01 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production

Details

PEEK (polyetheretherketone) is a high-performance engineered polymer with one of the highest strength ratios with heat resistant properties. CITCABLE PEEK Insulated Wire results from the extrusion of PEEK over a wide range of solid and stranded conductors.

Details

CITCABLE: High Temperature PEEK TPI PTX Cable CITCable extrudes all types of PEEK,PEI,TPI,PI,FEP,PFA,PTFE,ETFE,PVDF,Viton/FKM/FPM, SILICONE and Wrap PI,PTFE,others, CITCABLE can accommodate large power cables as well as miniature control cables. We provide fluid resistant atf oil and gas cable products. If you are interested in fluid resistant atf oil and gas cable, please contact us and initiate a consultation for more information. Features 1, Excellent mechanical properties and chemical resistance.2, Outstanding and Excellent resistance at high temperature to engine fluids3, High tear and tensile strength damping characteristic.4, Hot Oil Resistant Thin-Wall 150 ℃ , 200℃ 5, High performance PEEK,TPI,PEI,Teflon, Silicone,fluoropolymer /Viton/FKM /FPM outer, Jacket6, High Temperature, High Performance

Details

Radiation resistant PEEK cable for nuclear industry,peek wire and cable,MIL-P-46183 peek wire, Resistant ozone slightly Acidic wire cable.

Details

PEEK 、TPI、 POLYIMIDE、 ETFE cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion.

Details

HFI260 cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion.

Details

High radiation resistance peek wire cable,peek wire cable company, solid copper with peek insulation wire for Motor ,Motor Rewind with peek insulation wire.

Details

PEEK Wire has a durability and resistance to harsh environments that makes it extremely useful in downhole and deep drilling context for the oil industry. PEEK Wire is also used in the energy production sector, including in the nuclear industry, due to its superior resistance to radiation. we will custom manufacture PEEK Wire to meet the specific requirements of your application. Our extensive experience and expertise in custom designing PEEK Wire products, along with our broader expertise with the full spectrum of custom wire and cable products, enables us to provide you with superb quality and PEEK Wire that satisfies the critical needs of your application.

Details3F, C Build, NO.10, MinChang Road, Nance, HuMen DongGuan City,GuangDong.China.

IPv6 network supported

IPv6 network supported