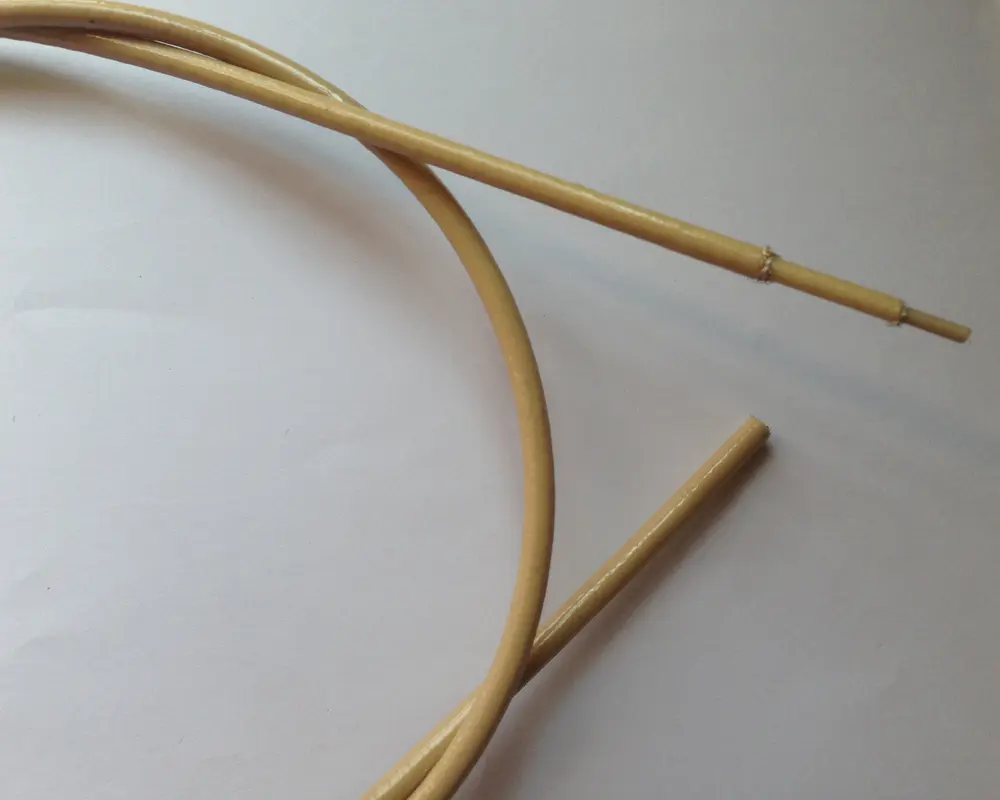

CITCABLE:Flat Kapton Wire

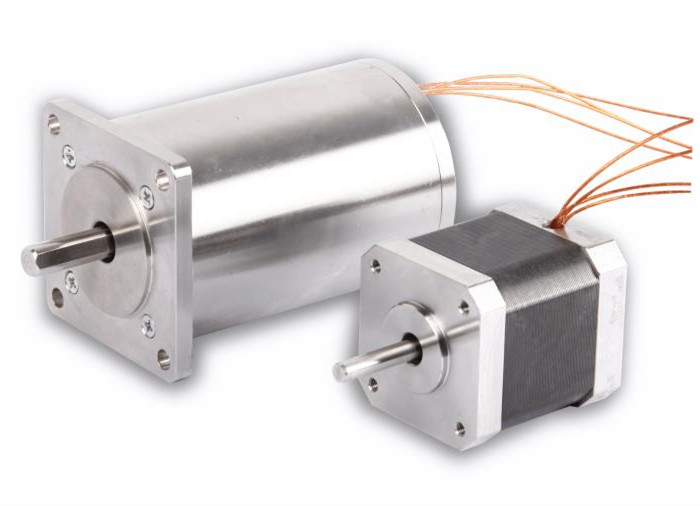

We provideThin-Wall Polyimide Coating wire sensor cable products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information.

Wire Specifications:

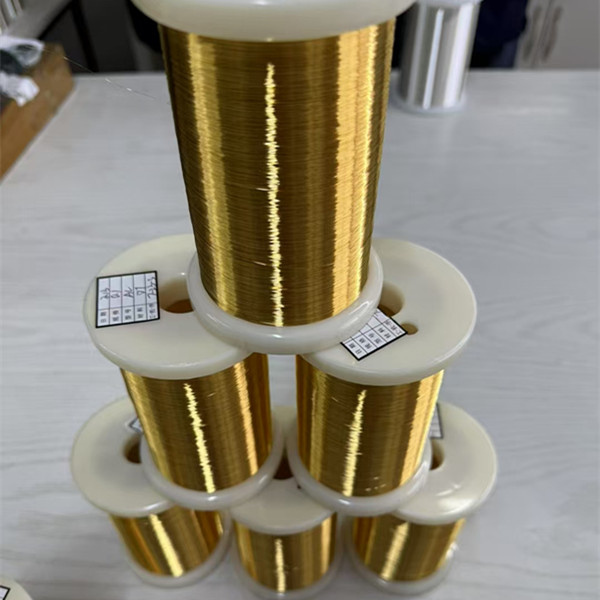

· Material: Pure Silver, Nickel or Silver, Nickel plated copper with a purity of ≥ 99.99%

· Tungsten Diameter: 0.08 mm ± 0.005 mm

· Polyimide / Kapton Diameter: 0.20 mm ± 0.01 mm

Coating Requirements:

· Type: Polyimide / Kapton/PEEK

· Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt%

· Biocompatibility: USP Class VI

·

Cleanliness Requirements

· Environment: Latex-free production

Read More

IPv6 network supported

IPv6 network supported