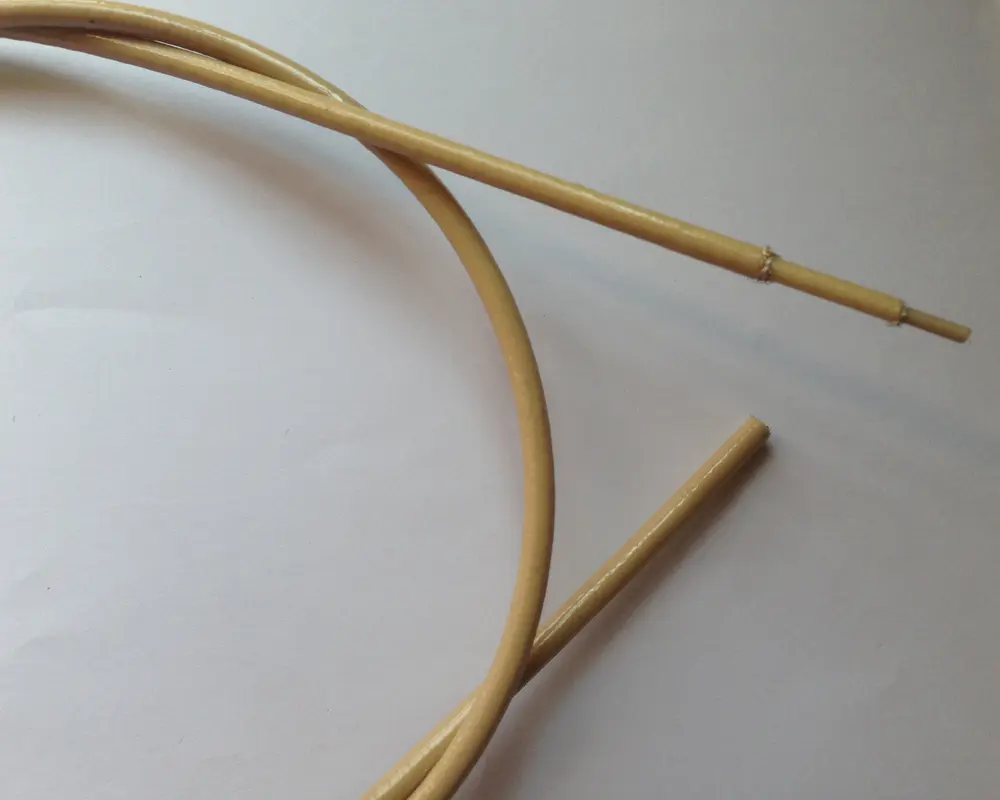

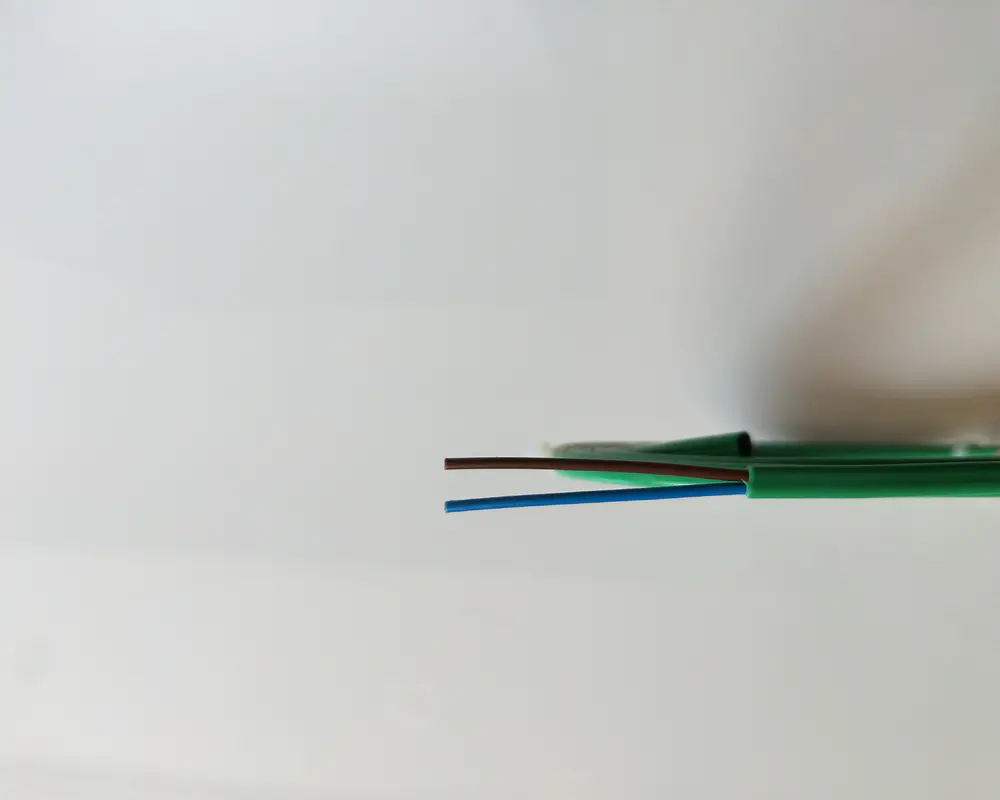

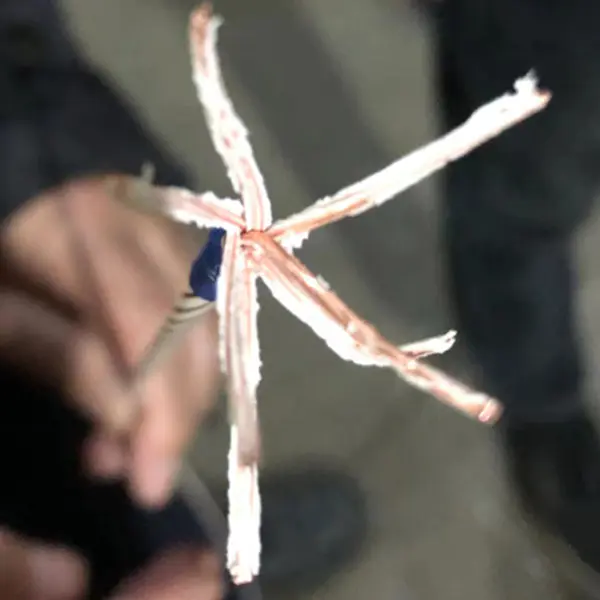

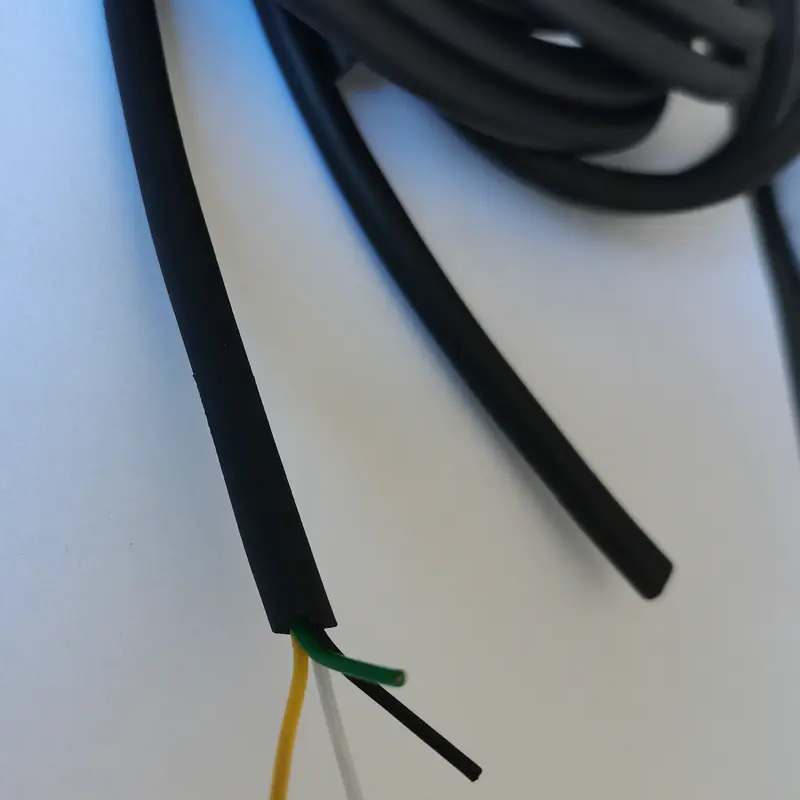

CITCABLE:200℃ Anti Capillary Wire Cable (FKM/VITON/XFLE/TEFLON)

Anti Capillary Wire Cable is typically constructed using high-quality, fluid-resistant materials such as fluoropolymers, silicone, and other specialty compounds. These materials not only resist the capillary action of fluids but also provide durability, flexibility, and resistance to extreme temperatures. The combination of these materials ensures that the Anti-Capillary Wire Cable can perform reliably in harsh environments while offering long-lasting protection against fluid exposure.

Fluid Compatibility

1. Engine Oil (ISO 1817. Oil No. 2)2. Engine Oil (IRM 902)3. Gasoline (Ref. Fuel C)4. Ethanol / Ref. Fuel C Mixture5. Diesel Fuel6. Battery Acid (Sp. Gr. ~ 1.26)7. Engine Coolant 50/508. E20

-40 °C to +200°C for Fluoroelastomer/ VITON/XLFE/FKM/VITON

Application

Greabox wiresFluid Resistant Transmission Wire200°C automatic transmission wireATF T6 wire Harness

Read More

IPv6 network supported

IPv6 network supported