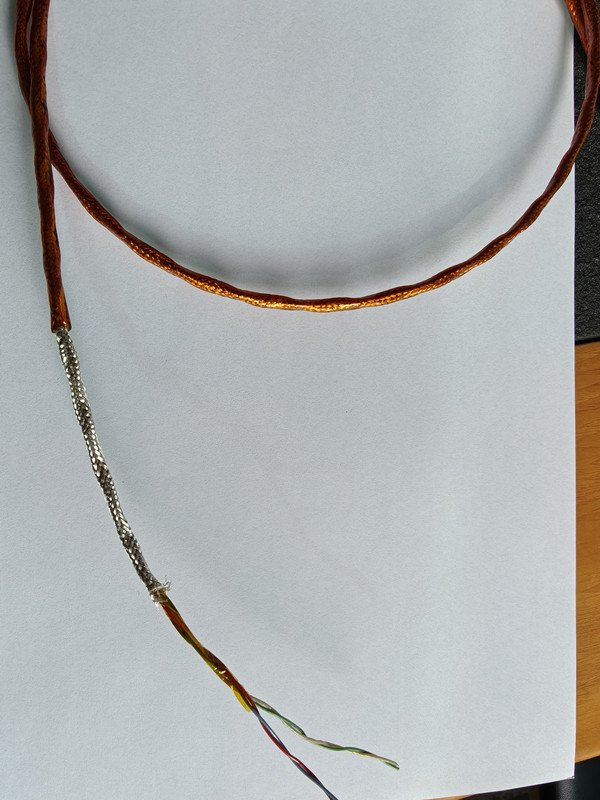

We provide high temperature nickel plated silver ntc sensor wire cable products. If you are interested in high temperature nickel plated silver ntc sensor wire cable, please contact us and initiate a consultation for more information.

Key Features

Halogen free and low toxicity

Excellent radiation resistance

PEEK cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion

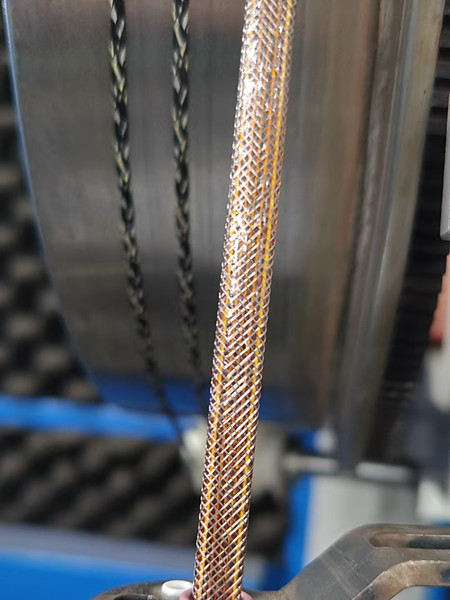

CITCABLE: 260°C Ultra thin 36AWG 4C PEEK Wire cable OD:1.9mm

Tin plated copper Alloy 0.08mm, PEEK OD:0.20MM

Tin plated copper 0.125mm, PEEK OD:0.30MM

Nickel plated copper 0.2mm, PEEK OD:0.38MM

Nickel plated Silver 0.20mm, PEEK OD:0.41MM Black or others

Nickel plated Silver 0.254mm, PEEK OD: 0.55MM Black or others

Features

Heat resistance

Continuous use is possible at high temperatures up to 260ºC.

Friction resistance

The friction coefficient of PEEK wire is very low.

Chemical resistance

PEEK wire has exceptional resistance to acids, solvents, fuels, etc.

Hydrolysis resistance

PEEK wire excels in dimensional and mechanical stability at high-pressure and high-temperature conditions.

Impact resistance

PEEK wire retains its toughness and strength under harsh conditions.

Flame resistance

PEEK wire has an inherent low flammability (UL94V-0).

Application

Aerospace Industry

Automotive Industry

Energy Industry

Fiber Optics

Fluid Management Industry

Medical Industry

Industrial / Non-medical Industry

Nuclear Industry

| Conductor | 0.12MM, temperature sensing armored cable |

| PEEK insulated OD | 0.25—5.0mm |

| Working temperature | -75℃---- +260℃ ( 500°F) |

| Rated voltage | 300V,600V and others |

| High Radiation Resistance | 109 Rad= 107 Gy |

CITCABLE offers the original types and a wide range of new Polyimide Coating wire cable Types for use in UHV and High Vacuum.

Details

CITCABLE offers the original types and a wide range of new TPI Wire Types for use in UHV and High Vacuum. RoHS Complian.

Details

CIT cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion. Polyimide (PI) is a group of high performing polymers known for their exceptional chemical, thermal, and mechanical performance properties. Polyimides generally demonstrate excellent thermal stability in high as well as low temperatures. Polyimides also exhibit broad chemical resistance and good dielectric properties. Polyimides are poor conductors of heat and are highly disinclined to burn; they are also radiation resistant. These properties and others have made polyimides widely used in industries including medical, aerospace, automotive, electronics, chemical, sensors, and more

Details

CIT cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion. Polyimide (PI) is a group of high performing polymers known for their exceptional chemical, thermal, and mechanical performance properties. These materials demonstrate exceptional thermal stability in high and low temperatures and are extremely flame resistant. PI , CITCABLE PI / TEFLON composite, is a high lubricity polyimide blend for applications that require lower surface friction yet do not require the performance of pure TEFLON. Polyimide maintains broad chemical resistance and good dielectric properties in addition to its reduced coefficient of friction

Details

CIT cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion. Polyimide (PI) is a group of high performing polymers known for their exceptional chemical, thermal, and mechanical performance properties. These materials demonstrate exceptional thermal stability in high and low temperatures and are extremely flame resistant. PI , CITCABLE PI / TEFLON composite, is a high lubricity polyimide blend for applications that require lower surface friction yet do not require the performance of pure TEFLON. Polyimide maintains broad chemical resistance and good dielectric properties in addition to its reduced coefficient of friction

Details

CIT cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion. HTM is a group of high performing polymers known for their exceptional chemical, thermal, and mechanical performance properties. HTM generally demonstrate excellent thermal stability in high as well as low temperatures. HTM also exhibit broad chemical resistance and good dielectric properties. HTM are poor conductors of heat and are highly disinclined to burn; they are also radiation resistant. These properties and others have made HTM widely used in industries including medical, aerospace, automotive, electronics, chemical, sensors, and more

Details

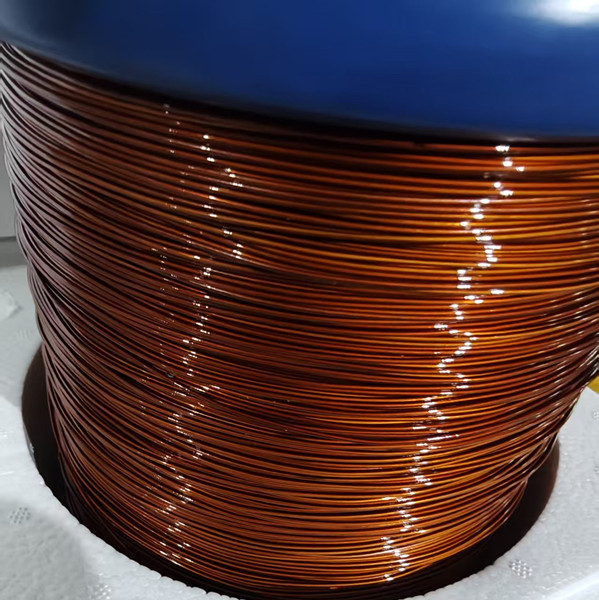

CIT cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion. HTM is a group of high performing polymers known for their exceptional chemical, thermal, and mechanical performance properties. HTM generally demonstrate excellent thermal stability in high as well as low temperatures. HTM also exhibit broad chemical resistance and good dielectric properties. HTM are poor conductors of heat and are highly disinclined to burn; they are also radiation resistant. These properties and others have made HTM widely used in industries including medical, aerospace, automotive, electronics, chemical, sensors, and more CITCABLE will custom manufacture this radiation resistant Enamelled wire for precise reuqiremnts of your project, 300℃ Enamelled Wire are custom ordered depending on the kind of conductor size such as heat wire,Alloy wire,S316, Aluminum alloy wire,tungsten wire, titanium wire so on and construction

Details

CIT cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion. Polyimide (PI) is a group of high performing polymers known for their exceptional chemical, thermal, and mechanical performance properties. These materials demonstrate exceptional thermal stability in high and low temperatures and are extremely flame resistant. PI , CITCABLE PI / TEFLON composite, is a high lubricity polyimide blend for applications that require lower surface friction yet do not require the performance of pure TEFLON. Polyimide maintains broad chemical resistance and good dielectric properties in addition to its reduced coefficient of friction

Details

CIT cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion. Polyimide (PI) is a group of high performing polymers known for their exceptional chemical, thermal, and mechanical performance properties. Polyimides generally demonstrate excellent thermal stability in high as well as low temperatures. Polyimides also exhibit broad chemical resistance and good dielectric properties. Polyimides are poor conductors of heat and are highly disinclined to burn; they are also radiation resistant. These properties and others have made polyimides widely used in industries including medical, aerospace, automotive, electronics, chemical, sensors, and more

Details

CIT cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion. Polyimide (PI) is a group of high performing polymers known for their exceptional chemical, thermal, and mechanical performance properties. Polyimides generally demonstrate excellent thermal stability in high as well as low temperatures. Polyimides also exhibit broad chemical resistance and good dielectric properties. Polyimides are poor conductors of heat and are highly disinclined to burn; they are also radiation resistant. These properties and others have made polyimides widely used in industries including medical, aerospace, automotive, electronics, chemical, sensors, and more

Details

Tungsten wire with Polyimide / Kapton Coating We provideTungsten wire with Polyimide / Kapton Coating sensor cable products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: White Tungsten with a purity of ≥ 99.95% · Tungsten Diameter: 0.18 mm ± 0.01 mm · Polyimide / Kapton Diameter: 0.27 mm ± 0.01 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production · Handling: Components must not be touched with latex glove

Details

Tungsten Wire With Polyimide / Kapton Coating CITCABLE: Thin-Wall Polyimide Coating wire We provideThin-Wall Polyimide Coating wire sensor cable products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: Pure Silver, Nickel or Silver, Nickel plated copper with a purity of ≥ 99.99% · Tungsten Diameter: 0.08 mm ± 0.005 mm · Polyimide / Kapton Diameter: 0.20 mm ± 0.01 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production

Details

CITCABLE:Super fine Polyimide / Kapton Coating Wire Cable We provideSuper fine Polyimide / Kapton Coating Wire Cable for sensor products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: Pure Silver, Nickel or Silver, Nickel plated copper with a purity of ≥ 99.99% · Tungsten Diameter: 0.05 mm ± 0.005 mm · Polyimide / Kapton Diameter: 0.10 mm ± 0.01 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production

Details

CITCABLE: Polyimide Coating wire cable We provideThin-Wall Polyimide Coating wire sensor cable products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: Pure Silver, Nickel or Silver, Nickel plated copper with a purity of ≥ 99.99% · Tungsten Diameter: 0.08 mm ± 0.005 mm · Polyimide / Kapton Diameter: 0.10 mm ± 0.01 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK/TPI/PEI · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production

Details

CITCABLE:Flat Kapton Wire We provideThin-Wall Polyimide Coating wire sensor cable products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: Pure Silver, Nickel or Silver, Nickel plated copper with a purity of ≥ 99.99% · Tungsten Diameter: 0.08 mm ± 0.005 mm · Polyimide / Kapton Diameter: 0.20 mm ± 0.01 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production

Details

CITCABLE: Polyimide Wire Kapton Cable We provideThin-Wall Polyimide Coating wire sensor cable products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: Pure Silver, Nickel or Silver, Nickel plated copper with a purity of ≥ 99.99% · Tungsten Diameter: 0.08 mm ± 0.005 mm · Polyimide / Kapton Diameter: 0.10 mm ± 0.01 mm to 30mm ± 0.8 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK/TPI/PEI · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production

Details

CITCABLE:TPI Coating Cable CIT cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion. Polyimide (PI) is a group of high performing polymers known for their exceptional chemical, thermal, and mechanical performance properties. These materials demonstrate exceptional thermal stability in high and low temperatures and are extremely flame resistant. PI , CITCABLE PI / TEFLON composite, is a high lubricity polyimide blend for applications that require lower surface friction yet do not require the performance of pure TEFLON. Polyimide maintains broad chemical resistance and good dielectric properties in addition to its reduced coefficient of friction

Details

CITCABLE: Thin-Wall Polyimide medical Wire We provideThin-Wall Polyimide/PI MEDICAL wire sensor cable products. If you are interested in high temperature MEDICAL sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: Pure Silver, Nickel or Silver, Nickel plated copper with a purity of ≥ 99.99% · Diameter: 0.12mm ± 0.005 mm · Polyimide / Kapton Diameter: 0.142 mm ± 0.005 mm Coating Requirements: · Type: Polyimide / Kapton/PI · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production

Details

CITCABLE: 320 Degree Enameled Wire CIT cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion. HTM is a group of high performing polymers known for their exceptional chemical, thermal, and mechanical performance properties. HTM generally demonstrate excellent thermal stability in high as well as low temperatures. HTM also exhibit broad chemical resistance and good dielectric properties. HTM are poor conductors of heat and are highly disinclined to burn; they are also radiation resistant. These properties and others have made HTM widely used in industries including medical, aerospace, automotive, electronics, chemical, sensors, and more High continuous operating temperature up to 400°C. Short time: 450°C Excellent abrasion resistance, flexural endurance. Improving the breakdown of local insulating paint enamelled in the process of voltage rise of motor in high frequency band. High conductivity, low impedance. Excellent softening breakdown resistance and heat shock resistance. Excellent dielectric properties and stable chemical properties. Chemical resistance (lubricating oil, impregnating paint, epoxy paint ). CITCABLE will custom manufacture this radiation resistant Enamelled wire for precise reuqiremnts of your project, 300℃ Enamelled Wire are custom ordered depending on the kind of conductor size such as heat wire,Alloy wire,S316, Aluminum alloy wire,tungsten wire, titanium wire so on and construction

Details

CITCABLE: Flat Polyimide Wire Cable Polyimide (TPI,KAPTION) is a group of high performing polymers known for their exceptional chemical, thermal, and mechanical performance properties. These materials demonstrate exceptional thermal stability in high and low temperatures and are extremely flame resistant. TPI KAPTION composite is a high lubricity polyimide blend for applications that require lower surface friction yet do not require the performance of pure TPI KAPTION maintains broad chemical resistance and good dielectric properties in addition to its reduced coefficient of friction. PI, KAPTION is available in tubing and as a coating for over-the-wire ( insulated wire cable) applications. For insulated wire,TPI KAPTION provides a low-friction wire for easier deployment or insertion into tubing. With TPI KAPTION wire, inside diameters offer low resistance to inserted devices or tools (pushability) while the outside remains bondable without etching. TPI KAPTION can also be produced in a layered composite construction with our conventional polyimide or with PI KAPTION. Composite layering polyimide and TPI KAPTION allows users to further tailor polyimide tubing or coating properties.

Details

CITCABLE: Flat TPI KAPTION Cable Polyimide (TPI,KAPTION) is a group of high performing polymers known for their exceptional chemical, thermal, and mechanical performance properties. These materials demonstrate exceptional thermal stability in high and low temperatures and are extremely flame resistant. TPI KAPTION composite is a high lubricity polyimide blend for applications that require lower surface friction yet do not require the performance of pure TPI KAPTION maintains broad chemical resistance and good dielectric properties in addition to its reduced coefficient of friction. PI, KAPTION is available in tubing and as a coating for over-the-wire ( insulated wire cable) applications. For insulated wire,TPI KAPTION provides a low-friction wire for easier deployment or insertion into tubing. With TPI KAPTION wire, inside diameters offer low resistance to inserted devices or tools (pushability) while the outside remains bondable without etching. TPI KAPTION can also be produced in a layered composite construction with our conventional polyimide or with PI KAPTION. Composite layering polyimide and TPI KAPTION allows users to further tailor polyimide tubing or coating properties.

Details

CITCABLE: Kapton Insulated Coaxial Cable Polyimide (TPI,KAPTION) is a group of high performing polymers known for their exceptional chemical, thermal, and mechanical performance properties. These materials demonstrate exceptional thermal stability in high and low temperatures and are extremely flame resistant. TPI KAPTION composite is a high lubricity polyimide blend for applications that require lower surface friction yet do not require the performance of pure TPI KAPTION maintains broad chemical resistance and good dielectric properties in addition to its reduced coefficient of friction. PI, KAPTION is available in tubing and as a coating for over-the-wire ( insulated wire cable) applications. For insulated wire,TPI KAPTION provides a low-friction wire for easier deployment or insertion into tubing. With TPI KAPTION wire, inside diameters offer low resistance to inserted devices or tools (pushability) while the outside remains bondable without etching. TPI KAPTION can also be produced in a layered composite construction with our conventional polyimide or with PI KAPTION. Composite layering polyimide and TPI KAPTION allows users to further tailor polyimide tubing or coating properties.

Details

CITCABLE: Kapton Cable CIT cable outstanding and excellent abrasion resistance, dielectric strength, chemical resistance, thermal endurance in long. protects against corrosion. Polyimide (PI) is a group of high performing polymers known for their exceptional chemical, thermal, and mechanical performance properties. These materials demonstrate exceptional thermal stability in high and low temperatures and are extremely flame resistant. PI , CITCABLE PI / TEFLON composite, is a high lubricity polyimide blend for applications that require lower surface friction yet do not require the performance of pure TEFLON. Polyimide maintains broad chemical resistance and good dielectric properties in addition to its reduced coefficient of friction

Details

CITCABLE: High performance Polyimide Cable We provideThin-Wall Polyimide Coating wire sensor cable products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: Pure Silver, Nickel or Silver, Nickel plated copper with a purity of ≥ 99.99% · Tungsten Diameter: 0.08 mm ± 0.005 mm · Polyimide / Kapton Diameter: 0.10 mm ± 0.01 mm to 30mm ± 0.8 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK/TPI/PEI · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production

Details

CITCABLE: Kapton Wire We provideThin-Wall Polyimide Coating wire sensor cable products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: Pure Silver, Nickel or Silver, Nickel plated copper with a purity of ≥ 99.99% · Tungsten Diameter: 0.08 mm ± 0.005 mm · Polyimide / Kapton Diameter: 0.20 mm ± 0.01 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production

Details

CITCABLE: Polyimide Coating wire We provideThin-Wall Polyimide Coating wire sensor cable products. If you are interested in high temperature motor sensor cable, please contact us and initiate a consultation for more information. Wire Specifications: · Material: Pure Silver, Nickel or Silver, Nickel plated copper with a purity of ≥ 99.99% · Tungsten Diameter: 0.08 mm ± 0.005 mm · Polyimide / Kapton Diameter: 0.10 mm ± 0.01 mm Coating Requirements: · Type: Polyimide / Kapton/PEEK/TPI/PEI · Solvent Residue: N-Methyl-2-Pyrrolidone (NMP) ≤ 0.1 wt% · Biocompatibility: USP Class VI · Cleanliness Requirements · Environment: Latex-free production

Details

CITCABLE: High Temperature PEEK TPI PTX Cable CITCable extrudes all types of PEEK,PEI,TPI,PI,FEP,PFA,PTFE,ETFE,PVDF,Viton/FKM/FPM, SILICONE and Wrap PI,PTFE,others, CITCABLE can accommodate large power cables as well as miniature control cables. We provide fluid resistant atf oil and gas cable products. If you are interested in fluid resistant atf oil and gas cable, please contact us and initiate a consultation for more information. Features 1, Excellent mechanical properties and chemical resistance.2, Outstanding and Excellent resistance at high temperature to engine fluids3, High tear and tensile strength damping characteristic.4, Hot Oil Resistant Thin-Wall 150 ℃ , 200℃ 5, High performance PEEK,TPI,PEI,Teflon, Silicone,fluoropolymer /Viton/FKM /FPM outer, Jacket6, High Temperature, High Performance

Details

CITCABLE Special Insulated wire is available by custom; we can extrude this material in round, square. We can also provide all special insulated wire in stranded and other wire

Details3F, C Build, NO.10, MinChang Road, Nance, HuMen DongGuan City,GuangDong.China.

IPv6 network supported

IPv6 network supported