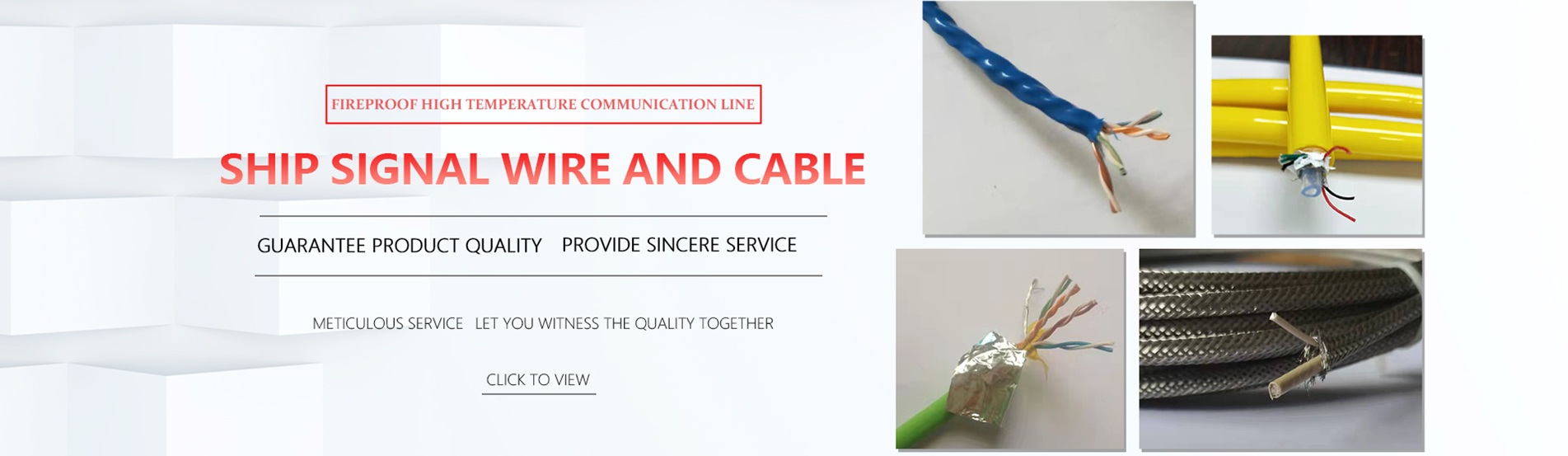

CITCABLE is a high performance fluid blocking or anti-capillary wire built to handle the high temperature fluid environments in engines and transmissions. It is an irradiation cross-linked fluoropolymer with impressive properties. CIT is extremely fluid resistant even at temperatures up to 150°C 200°C 250°C. It is an excellent, cost effective replacement for TFE, FEP ,Tefzel,TPI.PEI or PEE .insulated wire.

CITCABLE insulating and jacketing materials which are predominantly electron beam crosslinked, possess the special properties required for developing and manufacturing technically superior products. Its high temperature resistant, flame retardant, reduced wall thickness and easy processability make it the ideal insulating material for wires and cables in the motor/coil winding industry. We can also provide customer specific Wire&Cable solutions.

Application

Protected and fixed installation inside electrical equipment, especially suitable for the connection of motor windings, switchboards, white goods and lighting fixtures.

Excellent high and low temperature and ozone resistance

Weatherproof

Flexible

High resistance to thermal pressure

High abrasion resistance

Oil resistant

| Rated temperature | -40℃ ~ 200℃ ,T4, T6 rated (3000 hours) |

| Rated voltage | 600V DC----1500VDC |

| Conductor | 0.25mm2 to 50.0mm2 fully annealed stranded copper Per ASTM B-33 |

| Operating temperature range | -40 °C to +200°C for Fluoroelastomer / VITON/XLFE/FKM |

| -60 °C to +200°C for Silicone (VW-1) | |

| -100 °C to +260°C for TPI,PAEK,PEEK,PEI and others |

We provide fluid resistant atf oil 200°c motor lead cable products. If you are interested in fluid resistant atf oil 200°c motor lead cable, please contact us and initiate a consultation for more information.

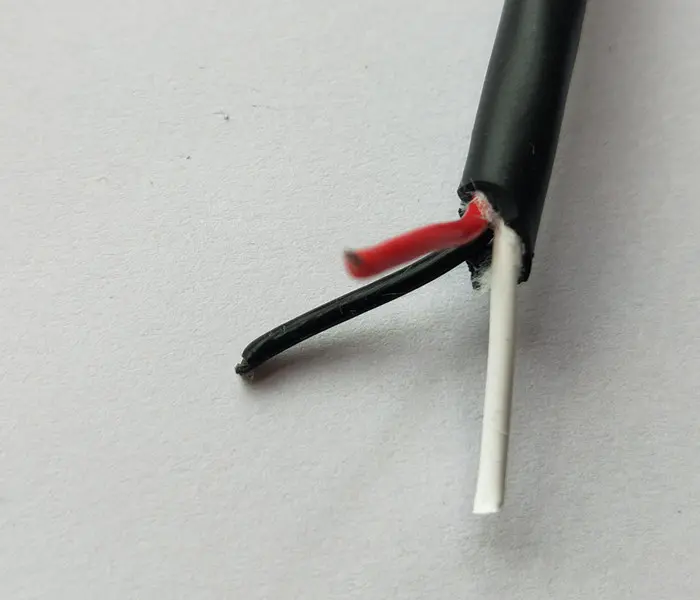

Details

Motor Lead wire is a high-temperature wire that may be used as motor lead wire for hazardous locations. Depending on its conductor size, this wire can be rated to either 150°C or 200°C, but it has an overall voltage rating of 5000V. It can also be used as a lead wire for electrical equipment in high-temperature environments. Motor Lead Wire wire performs well where flexibility and fire resistance are important

Details

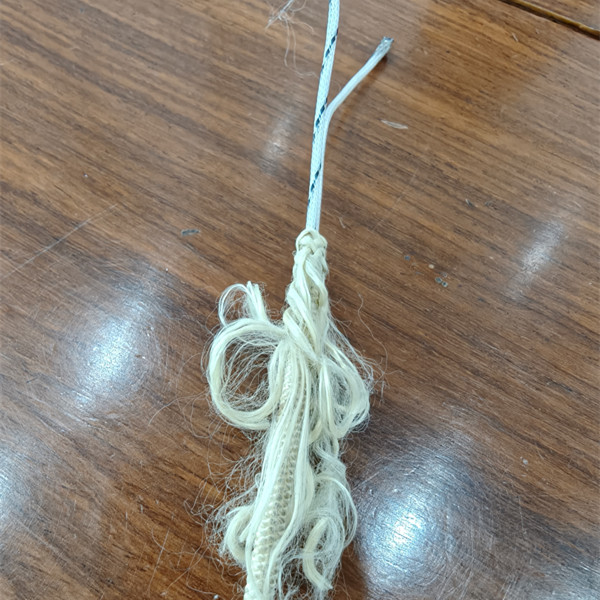

CITCABLE has expertise in developing cables for special Motor Winding Cableand Pump Cable applications.Experienced in providing these for marine and industrial / OEM applications, we can provide winding wire to your specific requirements protected by the insulations best suited to your products’ operating environment.

Details

We provide flexible motor rubber oil resistant wire cable products. If you are interested in flexible motor rubber oil resistant wire cable, please contact us and initiate a consultation for more information.

Details

If you are interested in automotive engine power supply cable, please contact us and initiate a consultation for more information.

Details

Super Heat Resistant wire cable for MotorCITCABLE is a high performance fluid blocking or anti-capillary wire built to handle the high temperature fluid environments in engines and transmissions. It is an irradiation cross-linked fluoropolymer with impressive properties. CIT is extremely fluid resistant even at temperatures up to 150°C 200°C 250°C. It is an excellent, cost effective replacement for TFE, FEP ,Tefzel,TPI.PEI or PEEK insulated wire.

Details

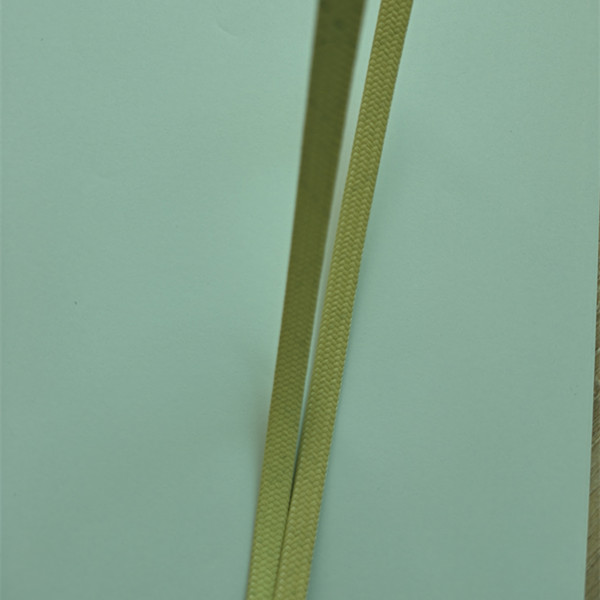

CITCABLE:Flexible Kevlar barid wire CABLE Flexible Flexible Kevlar barid wire cable is used to specifically refer to the wire and cable with fluoropolymer as the jacket. Flexible fluorpolymer cable has excellent weather resistance, heat resistance, small friction coefficient, stable chemical properties and good electrical insulation properties.

Details

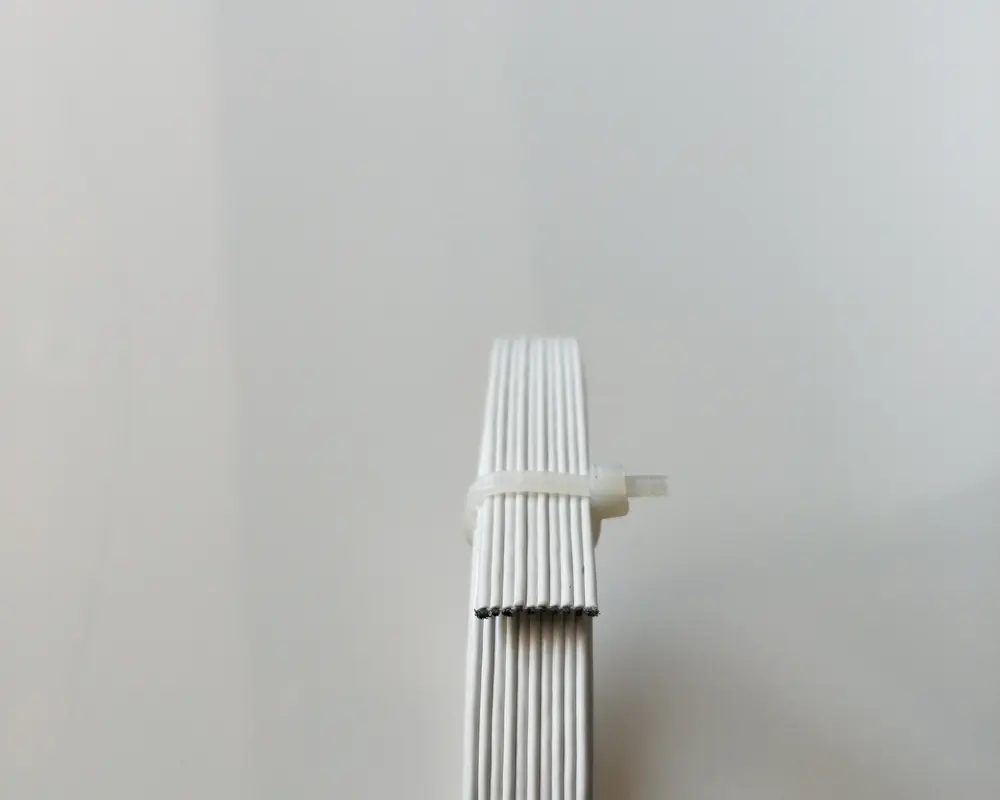

CITCABLE: Flat Kevlar Barid Cable Flexible Flexible Kevlar barid wire cable is used to specifically refer to the wire and cable with fluoropolymer as the jacket. Flexible fluorpolymer cable has excellent weather resistance, heat resistance, small friction coefficient, stable chemical properties and good electrical insulation properties.

Details

CITCABLE is a high performance Irrax R9 flat 26AWG WIRE,fluid blocking or anti-capillary wire built to handle the high temperature fluid environments in engines and transmissions. It is an irradiation cross-linked fluoropolymer with impressive properties. CIT is extremely fluid resistant even at temperatures up to 150°C 200°C 250°C. It is an excellent, cost effective replacement for TFE, FEP ,Tefzel,TPI.PEI or PEE .insulated wire.

Details

We provide fluoroelastomer FKM wire cable products. If you are interested in fluoroelastomer xlfe wire cable, please contact us and initiate a consultation for more information.

Details

We provide fluoroelastomer FKM wire cable products. If you are interested in fluoroelastomer xlfe wire cable, please contact us and initiate a consultation for more information.

Details

We provide fluoroelastomer wire cable products. If you are interested in fluoroelastomer wire cable, please contact us and initiate a consultation for more information.

Details

CITCABLE is a high performance fluid blocking or anti-capillary wire built to handle the high temperature fluid environments in engines and transmissions. It is an irradiation cross-linked fluoropolymer with impressive properties. CIT is extremely fluid resistant even at temperatures up to 150°C 200°C 250°C. It is an excellent, cost effective replacement for TFE, FEP ,Tefzel,TPI.PEI or PEE .insulated wire.

Details3F, C Build, NO.10, MinChang Road, Nance, HuMen DongGuan City,GuangDong.China.

IPv6 network supported

IPv6 network supported